Datasheet 搜索 > DIAC双向触发二极管,DIAC > Littelfuse(力特) > K1050GURP 数据手册 > K1050GURP 数据手册 5/8 页

¥ 3.138

K1050GURP 数据手册 - Littelfuse(力特)

制造商:

Littelfuse(力特)

分类:

DIAC双向触发二极管,DIAC

封装:

DO-204AC

Pictures:

3D模型

符号图

焊盘图

引脚图

产品图

页面导航:

导航目录

K1050GURP数据手册

Page:

of 8 Go

若手册格式错乱,请下载阅览PDF原文件

565

Revised: 09/15/14

Specifications are subject to change without notice.

©2014 Littelfuse, Inc

Teccor

®

brand Thyristors

Standard Unidirectional SIDACs

KxxxzyU SIDAC Series

565

100-250 V ac

60 Hz

100-250 V ac

60 Hz

SCR Sidac

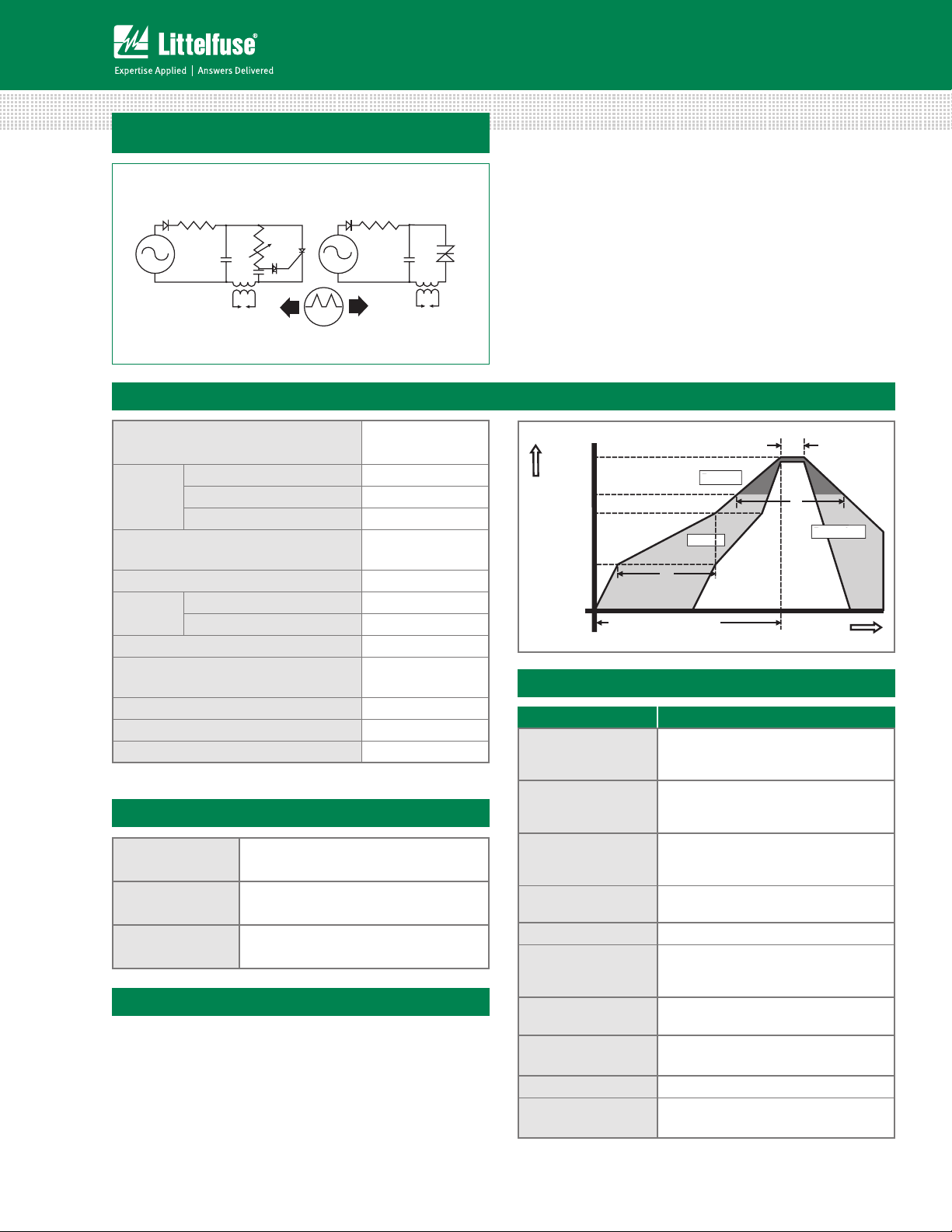

Figure 15: Comparison of SIDAC versus SCR for Gas

Ignitor Circuit

Soldering Parameters

Reflow Condition Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

) 150°C

- Temperature Max (T

s(max)

) 200°C

- Time (min to max) (t

s

) 60 – 180 secs

Average ramp up rate (Liquidus Temp)

(T

L

) to peak

5°C/second max

T

S(max)

to T

L

- Ramp-up Rate 5°C/second max

Reflow

- Temperature (T

L

) (Liquidus) 217°C

- Temperature (t

L

) 60 – 150 seconds

Peak Temperature (T

P

) 260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

20 – 40 seconds

Ramp-down Rate 5°C/second max

Time 25°C to peak Temperature (T

P

) 8 minutes Max.

Do not exceed 280°C

Time

Temperature

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat

P

r

e

h

eat

Ramp-upRamp-up

Ramp-down

R

am

p

-

do

Physical Specifications

Reliability/Environmental Tests

Test

Specifications and Conditions

High Temperature

Voltage Blocking

MIL-STD-750: Method 1040, Condition

A Rated V

DRM

(VAC-peak for thyristor),

125°C, 1008 hours

Temperature Cycling

MIL-STD-750: Method 1051

-40°C to 150°C, 15-minute dwell, 100

cycles

Biased Temperature &

Humidity

EIA/JEDEC: JESD22-A101

80% min V

BO

(V

DC

), 85°C, 85%RH, 1008

hours

High Temp Storage

MIL-STD-750: Method 1031

150°C, 1008 hours

Low-Temp Storage -40°C, 1008 hours

Thermal Shock

MIL-STD-750: Method 1056

0°C to 100°C, 5-minute dwell,

10-second transfer, 10 cycles

Autoclave

(Pressure Cooker Test)

EIA/JEDEC: JESD22-A102

121°C, 100%RH, 2atm, 168 hours

Resistance to

Solder Heat

MIL-STD-750: Method 2031

260°C, 10 seconds

Solderability ANSI/J-STD-002: Category 3

Lead Bend

MIL-STD-750: Method 2036, Condition E

Terminal Finish 100% Matte Tin Plated / Dipped

Body Material

UL recognized epoxy meeting ammability

classication 94V-0

Lead Material Copper Alloy

Design Considerations

Careful selection of the correct device for the application’s

operating parameters and environment will go a long

way toward extending the operating life of the Thyristor.

Overheating and surge currents are the main killers of

SIDACs. Correct mounting, soldering, and forming of the

leads also help protect against component damage.

5

器件 Datasheet 文档搜索

AiEMA 数据库涵盖高达 72,405,303 个元件的数据手册,每天更新 5,000 多个 PDF 文件