Datasheet 搜索 > TVS二极管 > Microsemi(美高森美) > JANTXV1N5811US 数据手册 > JANTXV1N5811US 其他数据使用手册 2/3 页

¥ 102.675

JANTXV1N5811US 其他数据使用手册 - Microsemi(美高森美)

制造商:

Microsemi(美高森美)

分类:

TVS二极管

封装:

E-MELF

Pictures:

3D模型

符号图

焊盘图

引脚图

产品图

页面导航:

应用领域在P1P3

导航目录

JANTXV1N5811US数据手册

Page:

of 3 Go

若手册格式错乱,请下载阅览PDF原文件

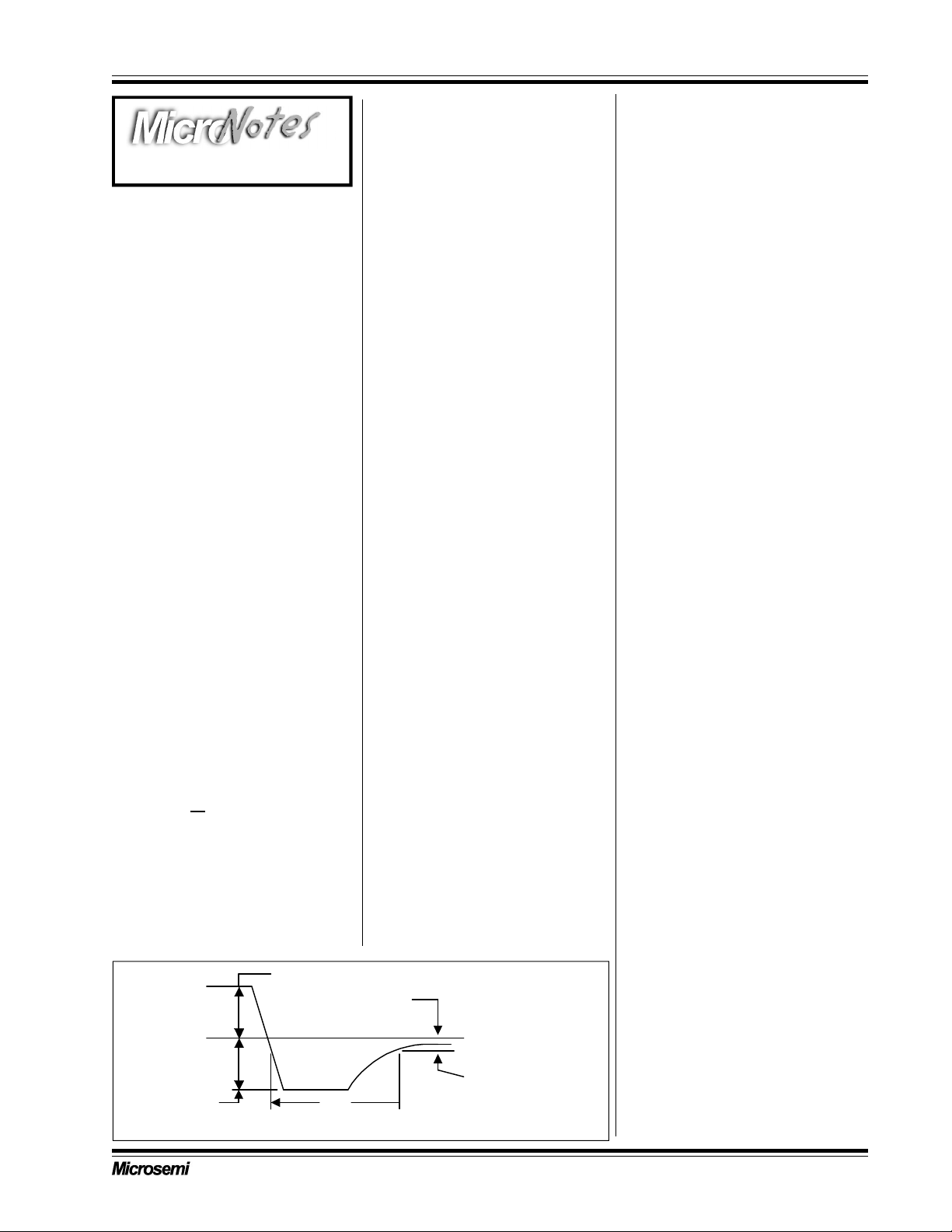

Only after this peak occurs will

reverse current diminish in the

latter portion of switching. The

overall time these semiconductor

events occur to switch off current

flow in the rectifier is represented

by reverse recovery time t

rr

.

In lower current applications, the

reverse current overshoot for

charge recovery is often limited by

the circuit or test method used

rather than the diode itself. When

test limited in this manner, it is then

simply identified as reverse

current I

RM

as shown in Figure 2.

This is an important distinction

from I

RM(REC)

since I

RM

is not a

diode dependent feature.

In either case, recovered charge

Q

RR

may be approximated by area

under the reverse current-time

curve. This Q

RR

also represents

energy that must be dissipated with

reverse voltage in the power

switching side of the circuit. In

Figure 1 where it appears

triangular and the apex is at

I

RM(REC)

, recovered charge Q

RR

can

be approximated by the

expression:

Q

RR

∼ (1/2) t

rr

I

RM(REC)

When I

RM

is limited by application

or test circuit, it will extend t

rr

somewhat to recover the charge

Q

RR

. It is also apparent that high

forward operating currents (I

O

)

injecting greater stored charge will

Series 302

require longer reverse recovery

time to switch. If I

O

and V

F

conduction losses result in higher

operating temperature, this will

also effectively increase t

rr

,

I

RM(REC)

, and

switching losses.

Both suggest rectifiers should be

conservatively chosen in I

O

ratings

versus application including any

noted I

F

difference in t

rr

test

characterization.

The reverse recovery time t

rr

is

comprised of two time intervals t

a

and t

b

when rectifiers respond with

their own peak reverse recovery

current I

RM(REC)

as shown in Figure

1. The t

a

begins at the moment

forward current has been ramped

down from I

F

where it intersects

the zero current axis, and

concludes at

the rectifier I

RM(REC)

peak response

point.

This t

a

region is primarily dictated

by rectifier component design in

how quickly the I

RM(REC)

peak can

be achieved with minority carrier

lifetime control. During this t

a

portion of switching, other circuit

components may be subjected to

fast rise time voltage-current

where the rectifier has not yet

begun to support reverse voltage.

As switching rates (di/dt)

increase, these other components

must absorb corresponding

greater switching energy and

heating. As operating frequency

increases, this can be excessive

at high duty factors.

The latter part of reverse recovery

time is t

b

. It begins at I

RM(REC)

peak and ends where reverse

current

decays to a specified level (see

Figure 1). In low to medium current

“soft recovery” rectifiers, it is often

where i

R

diminishes to 10-

25% of the specified peak I

RM

test

value. On higher rated current

rectifiers, reverse recovery may

also be specified to end at an

intercept point on the zero-current

axis after drawing a straight line

from the I

RM(REC)

point to 0.25

I

RM(REC)

on the recovery curve. This

line is then extended to the

termination point on the zero-axis.

For rectifiers with “abrupt recovery”

or oscillatory ring-off, it is where

reverse current again crosses the

zero axis. These examples are in

Figure 3.

The t

b

region in reverse recovery is

influenced by rectifier design and

circuit interaction. It is this

switching region where the rectifier

is now supporting significant

reverse voltage while reverse

current is still diminishing. During

this brief time, voltage and reverse

current switching energy are now

primarily absorbed by the rectifier.

This can also generate notable

rectifier heating if t

b

is excessively

long, particularly if repeated at

high frequency.

From the combined effects of both

t

a

and t

b

for reverse recovery time,

it is apparent that minimal values of

t

rr

are needed to reduce switching

energy stresses to other

components as well as the rectifier

diode itself in higher speed

applications. Since t

b

(and I

RM

)

are also influenced by the circuit, it

is important to specify test

requirements for t

rr

that reasonably

approximate actual operating

conditions including forward

current, di/dt, and temperature.

The latest industry standards for

measuring reverse recovery time

are found in JEDEC Standard

JESD41 which is virtually identical

Figure 2. Circuit Limited I

RM

0.10 I

RM

or 0.25 I

RM

I

R(REC)

I

F

t

rr

器件 Datasheet 文档搜索

AiEMA 数据库涵盖高达 72,405,303 个元件的数据手册,每天更新 5,000 多个 PDF 文件